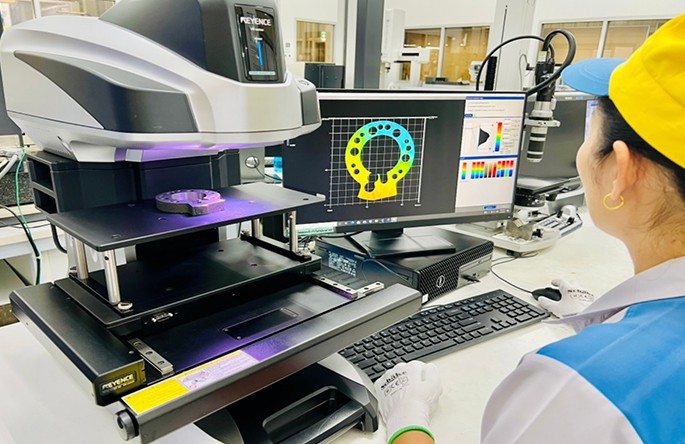

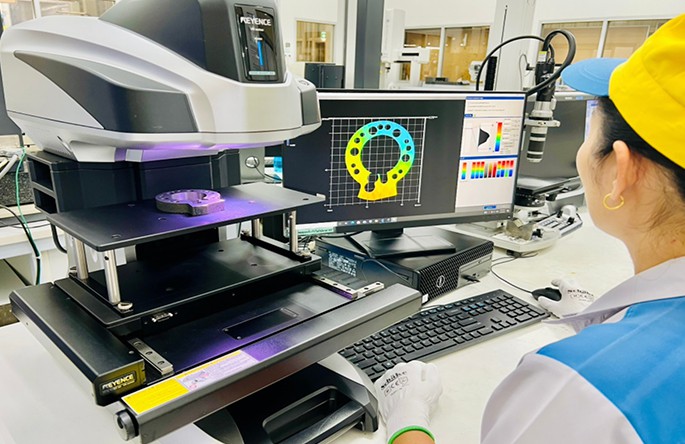

DCI 's products are controlled production through quality checks in every process since receiving process included production process with measuring tools that have high resolution and precision, such as a 3D measuring tool (Coordinate Measuring Machine) that can measure and display 3D results with modern functions, use a touch probe that is high precision.

Daikin Compressor Industries Ltd., has passed the ISO9001 : 2015 quality management system certification that used to manage the quality of various departments , so that customers can be confident that the company has quality production control processes in accordance with international standards.

Continuous improvement of quality to ensure customer satisfaction. Including being able to produce products without errors which will increase productivity and reduce defect parts in process , such as QCC activities. It is an activity that focuses on practitioners participating in solving work problems and improving quality or QC Story activities to solve chronic problems and have causes caused by the system. This will work as a cross functional team.

The production process undergoes quality control or rapid detection of defects. This reduces the chance of errors in production and waste from erroneous work with modern technology that can quickly check the quality of the work piece, such as a 3D surface scanner that helps to get the shape. of realistic cross-sectional area and no blind spots This makes it possible to accurately measure wall thickness and depth even in areas where measurement is required.