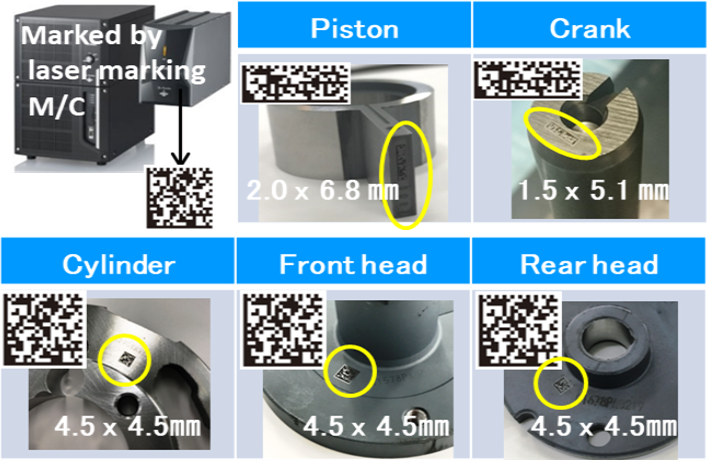

เพื่อให้เป็น Smart production line ที่สามารถสอบกลับข้อมูล เก็บข้อมูลต่างๆ ระหว่างการผลิตแบบ Real-time ได้จึงมีการนำ 2D code มาใช้ตั้งแต่กระบวนการผลิตชิ้นส่วน จนถึงกระบวนการประกอบจนเป็นผลิตภัณฑ์

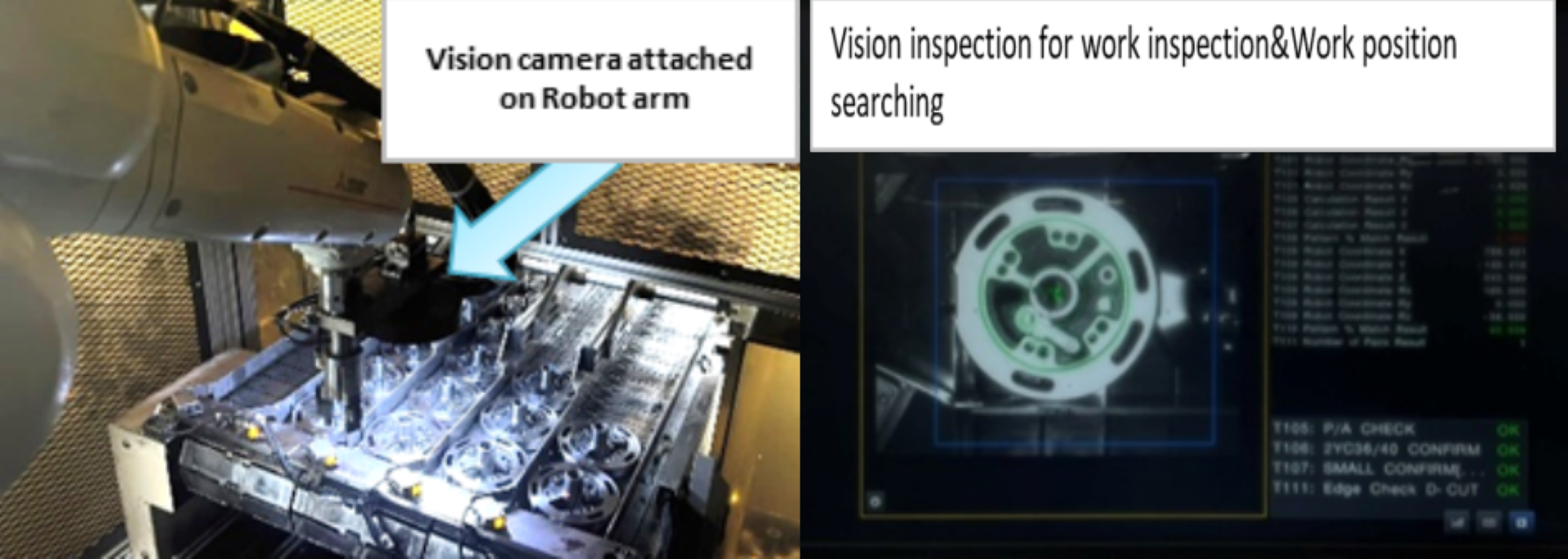

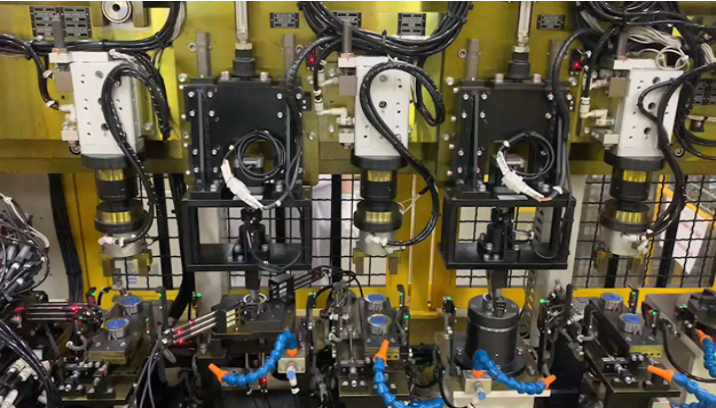

Use the Vision system with a high-resolution camera to check the accuracy of the work piece. and find a position for the robot to pick up workpieces to feed into laser marking processes, grinding processes, measuring processes or various assembly processes.

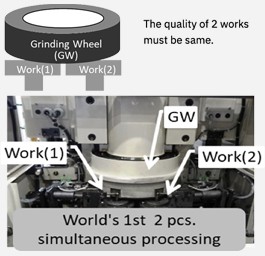

Using more than one piece of processing at the same time, for example, grinding the surface of two workpieces at the same time reduces the production time per piece. The number of machines used has decreased.

Using a honning process that is similar to engine production, it produces good quality holes in the workpiece. It has an accurate size.

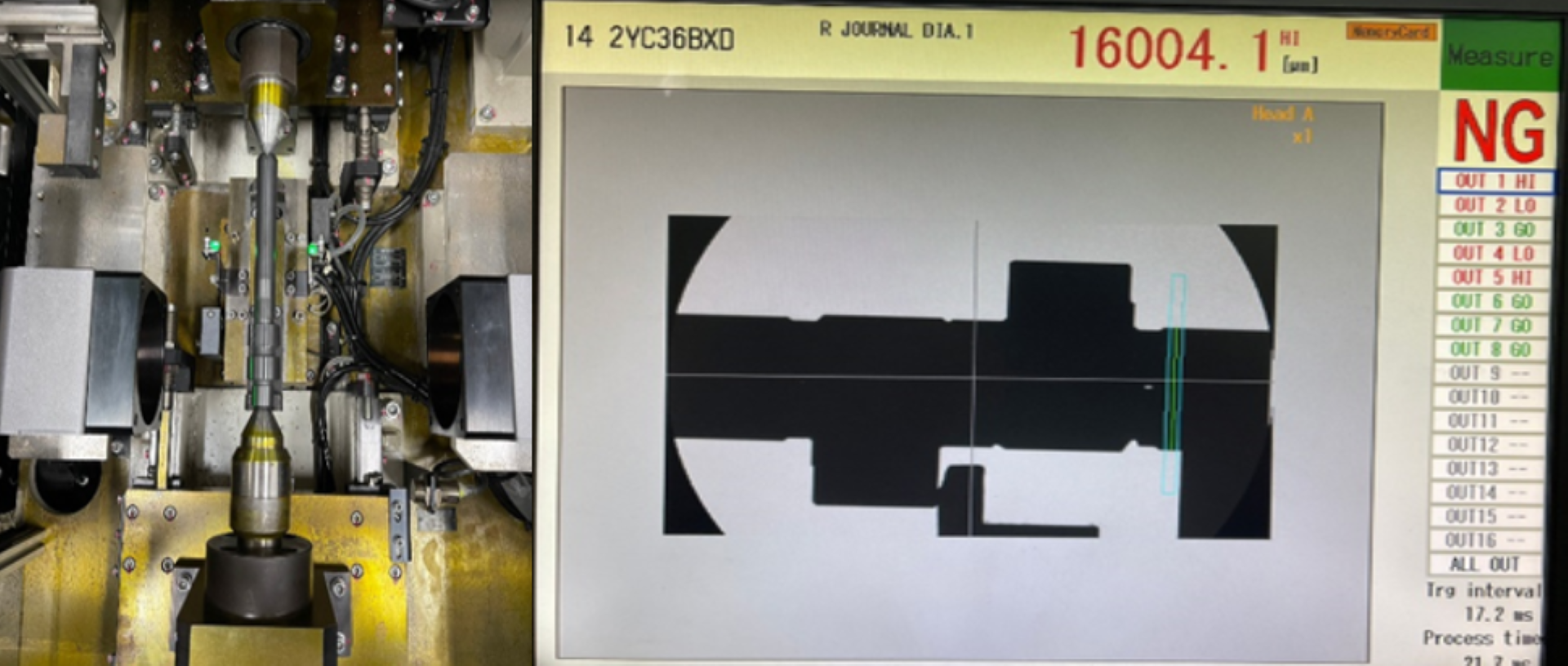

Use the 2D profile measuring system for measuring workpiece diameter without touching the workpiece. This eliminates the need to adjust the probe distance when the size of the workpiece changes.

Adopt high speed automatic measuring system Makes it possible to measure work pieces with precision and accuracy and also uses an automatic work piece matching system to get clearance according to design standards. Thus making it possible to reduce redundant measurement processes. and reduce the number of employees in the production line.